-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

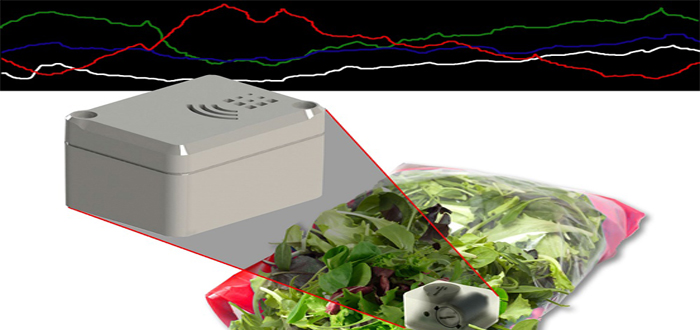

Real time environmental data collection from inside a food pack right across the distribution chain

EMCO Packaging has developed an advanced and highly sensitive data logger that collects environmental data actually from the inside a food pack. It measures oxygen content, temperature, relative humidity & pressure and operates from the time the food is packed on the production line right through storage, transport and even whilst it is on display in a frozen, chilled or normal cabinet.

The data logger can communicate wirelessly as well as storing up to 300,000 records in memory for later USB download.

By accurately monitoring the environmental conditions from inside the pack, the system provides the data necessary to analyse any changes, trends or conditions and optimise each part of the process – from the packaging materials themselves, through to storage, transport and display conditions. As a result produce can be delivered to the consumer in peak freshness and quality conditions.

Not only does the gas logger produce more accurate and realistic results throughout the supply chain than can be gained by ripping packs open at every stage of the process to take measurements – but it is far less destructive as well!

The data logger is just 65mm x 50mm x 37mm and is manufactured to a particularly high and rugged engineering standard. Oxygen and humidity are both measured to a resolution of 0.05% and 0.04% respectively, temperature to an accuracy resolution of 0.01% and pressure to a 16 bit resolution over a range of 10 – 1200mbar. www.emcopackaging.com