-

Nulogy Introduces the Manufacturing Operating System - 1 day ago

-

Bliss Direct scales to 300 daily orders and saves 25 hours per week with Forterro’s Orderwise ERP - February 25, 2026

-

Wootzwork raises $6.6M to bring predictability to offshore manufacturing - February 25, 2026

-

Rite-Hite unveils new range of hydraulic kits to upgrade and extend dock leveller performance - February 19, 2026

-

REWE and Cimcorp automate fresh supply chain for Berlin supermarkets and stores - February 19, 2026

-

NULOGY’S SHOP FLOOR SOFTWARE TO POWER COMPLETE CO-PACKING’SOPERATIONS - February 13, 2026

-

Wallapop and Albatross Sign Strategic Partnership to Bring Real-Time AI Discovery to the Future of Consumer-to-Consumer Commerce - February 12, 2026

-

Thorworld ramp helps Hubergroup to streamline its unloading operation - February 6, 2026

-

A journey from apprentice to fully qualified paint sprayer - February 5, 2026

-

TRACKER INNOVATION FROM QUECLINK TO BOOST STOLEN VEHICLE RECOVERY PERFORMANCE - February 4, 2026

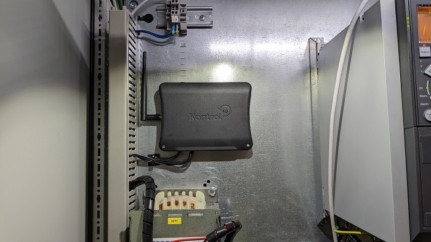

Leading pallet stability expert Lindum is setting a new standard in efficiency with the launch of Kontrol 4.0, an innovative new device designed to provide unparalleled insight into pallet wrapping.

Developed and built upon Lindum’s commitment to excellence and innovation, Kontrol 4.0 represents a significant advancement in pallet wrapping technology. Designed to work seamlessly with all pallet wrapping machinery, Kontrol 4.0 is a compact IoT device that retrofits to any pallet wrapping machine to provide real-time insight into overall film consumption and wrapper performance, enabling manufacturers to quickly identify and correct inefficiencies.

Leveraging advanced data analytics, Kontrol 4.0 provides real-time feedback and customisable alerts to notify users of issues in overall wrap integrity, including informing the user of any breaks and machinery malfunctions, minimising downtime, and maximising productivity.

Kontrol 4.0 also offers actionable insight into operational trends and can be accessed remotely via a user-friendly interface that allows managers to monitor operations and make necessary adjustments from anywhere at the touch of a button.

Rick Sellars, Sales Manager at Lindum comments: “Kontrol 4.0 was developed by our team at Lindum to aid packaging managers in being more efficient. With the implementation of the Plastic Packaging Tax, more and more companies are seeking ways to make palletising more efficient and cost-effective.

By using this device, packaging managers can monitor the efficiency of their pallet wrapping operations and identify areas where improvements can be made to make the process more sustainable. Kontrol 4.0 can also help ensure that the film is being stretched correctly to minimise costs and prevent pallet stability issues.”

Kontrol 4.0 is available now and can be purchased directly from Lindum. Based in Grimsby, Lindum specialises in pallet stability and stretch film to help companies save money, reduce plastic, improve packaging performance, and reduce CO2 emissions.

For more information visit lindumpackaging.com