-

ARROWXL SECURES FIFTH CONSECUTIVE GOLD ROSPA AWARD - 1 day ago

-

Delivery management platform, Scurri topped over €12 billion in Gross Merchandise Value (GMV) in the total value of shipments processed in 2023 - April 17, 2024

-

Britvic reaffirms partnership with LPR - April 17, 2024

-

Kammac Supports Nimble’s Expansion into 500 Tesco Stores - April 5, 2024

-

Axiom Sustainability Software launches groundbreaking Social Value Calculator - April 4, 2024

-

Change to minimum wage and its impact on logistics - April 3, 2024

-

PARKSAFE GROUP TEAMS UP WITH QUECLINK WIRELESS SOLUTIONS IN FLEET TECHNOLOGY PARTNERSHIP - March 27, 2024

-

Facing shocking levels of violence at work – yet not paid enough to live on: 57% of UK retail staff say their wages barely cover basic expenses, despite many working more hours than ever - March 26, 2024

-

Bridgestone proving the worth of its Duravis Van tyre through academic study - March 25, 2024

-

Fleetmaxx Solutions announces Vanaways partnership - March 25, 2024

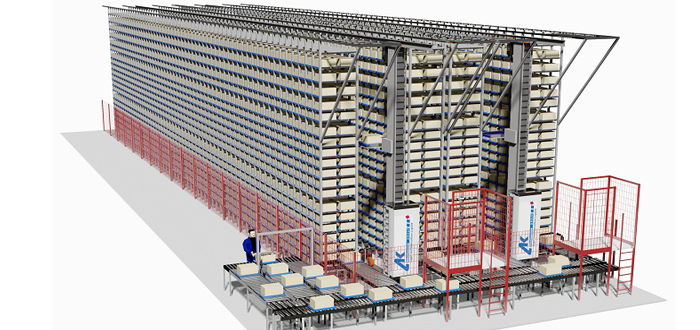

Raising efficiency at a Minimum Loss of Cooling.

Frischdienst Walther builds with Klinkhammer a cold store down to -22°C

The Klinkhammer Group has built an automated deep freeze warehouse for

temperatures down to -22°C for the company Frischdienst Walther, a food delivery wholesaler

located in Kitzingen, supplying restaurants, hotels and large-scale consumers. Thanks to

the tray technology used, it is now possible to store a wide variety of different package sizes

in a cost-effective manner. The focus is on short distances, a minimum cooling loss and significant

increase of efficiency in the warehouse through automation.

Restaurants and large-scale consumers rely on the competence of Frischdienst Walther who supplies

more than 7,800 articles for the preparation of menus. More than 100 years of successas family owned

company –this is only possible with the respective dedicationand passion for what you are

doing. Following the motto: “Being your expert in frozen food who speaks your language and ensures

that you bring the quality to the table which your guests expect from you” the company Frischdienst

Walther guarantees highest reliability during order picking of the goods ordered thanks to the

technical support provided by the “Pick-by-Voice” technology. By means of the electronic routing

and scheduling system and thanks to the own vehicle fleet equipped with two-chamber cooling systems,

delivery deadlines and cold chains are fully complied with.

Tray technology ensures flexibility for package sizes

Given the rapidly growing need for deep-freeze products, Frischdienst Walther decided to automate

its processes in the deep-freeze warehouse by contracting Klinkhammer. “Our aim was to considerably

increase the capacity, speed, efficiency and flexibility while at the same time making optimum

use of space” outlines Friedrich Walther, Managing Director of Frischdienst Walther. “The orders of

our customers from restaurants are often placed at very short notice and more than 95% of them are

delivered within 24 hours.” For the just-in-time delivery to its customers Frischdienst Walther may

now benefit from a modern, automated high-bay warehouse featuring two aisles, providing 9,120

tray storage locations. The throughput amounts to up to 150 storage and retrieval actions per hour.

The specialists of Klinkhammer use trays as loading/storage aids as these trays offer highest possible

flexibility during the storage process of packaging units of different size and height.

Energy efficiency and a minimum loss of cooling in the deep-freeze warehouse

The order picking workstations, which are connected by means of a conveyor loop in the pre-zone of

the automated deep-freeze warehouse, guarantee an ergonomic handling of the trays. The maximum

height of the small parts warehouse totals to 7.60 m to fully comply with the statutory fire protection

requirements. Thanks to this height limitation it was possible to avoid the installation of complex

and costly sprinkler systems or the inertisation of the warehouse. All warehouse sections and

functional areas are linked such to ensure shortest possible distances and such that the loss of cooling

as well as the introduction of heat and humidity is kept at a minimum level. The machines and

systems have been designed to best fit the requirements in deep-freeze stores. Deep-freeze suitable

technical components such as special drives, control cabinet heaters, appropriate photoelectric

barriers and sensors as well as temperature-resistant plastics guarantee high system reliability even

at temperatures of minus 22°C. To ensure high energy efficiency, the power requirements of the

system were harmonized with the power requirements of the air conditioning to compensate power

peaks in current consumption.

Linking the Klinkhammer Warehouse Management Software to the ERP system

The Klinkhammer Warehouse Management System, including the material flow computer, is linked

to the already existing ERP system via interfaces. Beyond the incoming goods and order picking

process, the warehouse management system also controls the flow of materials and the storage and

retrieval actions of the products which are allocated to a storage location depending on the product

group, best-before date and batch number. The Klinkhammer material flow computer is responsible

for the transport of the trays and the management of the storage locations. The warehouse management

system is in charge of managing the respective stocks on the trays whereas quantity

changes are controlled by the higher-level host system. To get a better overview of the storage locations

available, the warehouse management system displays the availability based on height classes.

Special sequencing algorithms allow strict adherence to the order and position sequence taking

into account batches and best-before dates. For identifying the goods to be stored in the warehouse,

the trays are labeled/marked with unique, machine-readable bar codes at two positions.

Saving time thanks to automated receipt

Following notification, the user places the frozen products on an empty tray for automatic receipt.

While this tray is identified and weighed at the conveyor system scanner, the weight determined by

the scales is compared to the calculated weight of the quantity received. If the weight is within the

tolerance range, the tray is automatically stored in the deep-freeze warehouse. Product-specific

units with different individual weight, as this is the case, for example, for a leg of venison, can be

represented in the warehouse management system by entering the weight manually. After that, the

ERP system receives a feedback reporting on the sum per position including time stamp. Thanks to

automating the warehouse, it was possible to achieve a significant efficiency increase when handling

different package sizes and weights.